For Professionals, By Professionals

Discover ProX PC for best custom-built PCs, powerful workstations, and GPU servers in India. Perfect for creators, professionals, and businesses. Shop now!

SERVICES

WE ACCEPT

Outline

Case 1: AI Inspection for Bus Frame Welding

Case 2: The AI Defect Detection System for Paper Jar Production

Case 3: High-speed and High-precision Control of Screen Printing Machine

Case 4: DAQ Solution Improves Inspection of Wafer Probe Stations

Case 5: Machine Condition Monitoring System for Steel Manufacturing

Case 6: Fast Roaming Accelerating Solution of AGVsRelated Stories

Enhancing efficiency and quality through smart equipment is a priority, but the challenge lies in supporting machine builders and system integrators to develop intelligent machinery.

ProX PC addresses this need with its industrial equipment manufacturing (IEM) solution, which focuses on three key areas: Data Connectivity & Visualization, Automation Control & Measurement, and AI Inspection. These solutions offer diverse hardware combinations to cater to the requirements of scalable and profitable smart machine projects.

Discover how ProX PC has empowered its clients to achieve success by embracing cutting-edge technologies and leveraging intelligent machinery.

Case 1: AI Inspection for Bus Frame Welding

ProX PC has partnered with NVIDIA to develop an AI inspection system specifically designed for bus-frame welding. This advanced system offers a significant improvement over traditional inspection methods, which are often time-consuming and labor-intensive. By leveraging the power of artificial intelligence, the new system enables efficient and precise inspections, ensuring the safety standards of large buses.

● Time reduction of up to 80% in inspecting a large bus with hundreds of welds..

● Reliable AI hardware platform designed to meet the demands of critical working environments.

● Exceptional performance capabilities, including support for multiple IP cameras, efficient processing and storage of large image data, and seamless AI inference and training services.

Case 2: The AI Defect Detection System for Paper Jar Production

In collaboration with ProX PC Infotech Pvt. Ltd successfully developed an "AI Defect Detection System" for a paper jar factory. This innovative system has brought significant improvements to the accuracy rate and detection time of product quality. The collaboration between Claireye Intelligence Co. Ltd. and ProX PC has resulted in a cutting-edge solution that revolutionizes defect detection in the paper jar manufacturing process.

● Achieve an outstanding inspection accuracy rate exceeding 98%.

● All-in-One AI camera, allowing for easy deployment across the production line.

● Supports SDKs such as CAMNavi SDK, HTML5 Web-based tools, NVIDIA Deepstream SDK, and Azure AVA Suite.

● Enable smooth integration with existing ERP system through the LAN enhancing operational efficiency.

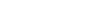

Case 3: High-speed and High-precision Control of Screen Printing Machine

In search of a more dependable EtherCAT I/O system to replace their current setup, the customer required a solution that seamlessly integrated with Beckhoff's XFC architecture. After careful consideration, the customer ultimately selected ProX PC due to several key factors including the AMAX-5000 series timestamp and encoder modules offered by ProX PC which perfectly matched the customer's specific requirements. Also, ProX PC’s reliable products and strong dedicated technical assistance provided the ideal solution to enhance their EtherCAT I/O system.

● Seamless integration of the AMAX-5000 I/O system with the existing legacy control system.

● The 1ns level precise time stamp module supports fast and accurate operations of high-quality printing machines.

● PC-based EtherCAT controller with modular slice I/O provides a high level of flexibility.

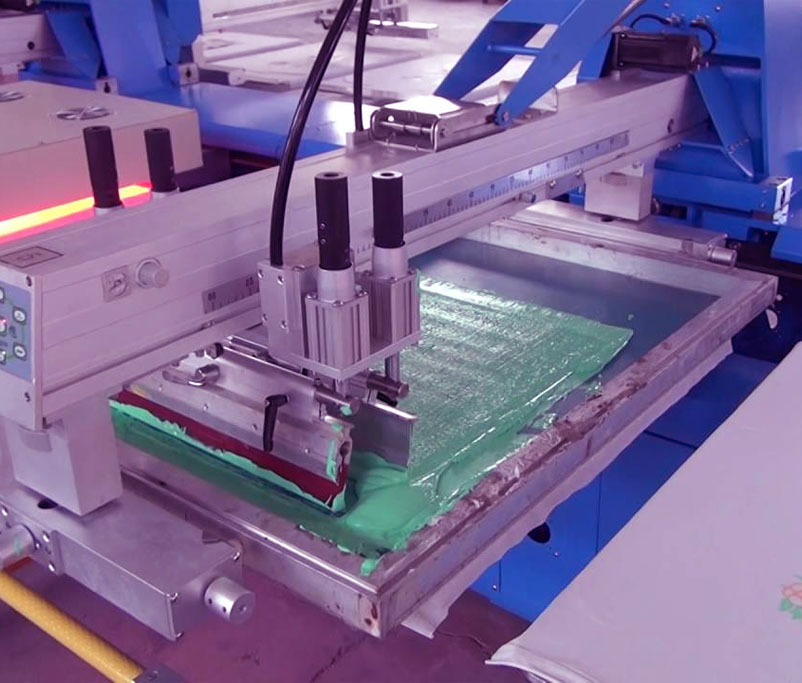

Case 4: DAQ Solution Improves Inspection of Wafer Probe Stations

When it comes to handling higher density dies on wafers, probe station developers face the challenge of selecting the appropriate data acquisition (DAQ) products for their equipment. ProX PC offers a comprehensive DAQ solution designed specifically for die inspection. This solution comprises three PCIE cards that offer multi-channel capabilities, high-resolution output, and high-speed synchronous sampling. These features enable a wide range of complex inspections with low-latency sampling intervals. Additionally, ProX PC provides DAQNavi, a user-friendly software development kit that significantly saves time.

● Convenient one-stop shopping, saving valuable time searching for different components.

● Experience enhanced accuracy with 16-bit resolution, ensuring more precise sampling results.

● Sampling rates of no less than 500kS/s for each channel, enabling efficient data acquisition.

● PCIE card that offers a minimum of 8 channels for simultaneous analog input, allowing for the testing of eight dies concurrently.

Case 5: Machine Condition Monitoring System for Steel Manufacturing

Traditional metal and steel producers face challenges in maintaining their existing equipment, which generates various types of data such as vibration, pressure, liquid level, and temperature while operating in facilities. Effectively measuring and analyzing this data is crucial for efficient monitoring and management. ProX PC offers a machine condition monitoring solution that empowers operators to maintain equipment effectively. This solution enables real-time monitoring of critical assets through data acquisition (DAQ) solutions, allowing operators to stay informed about the status of their equipment and make informed decisions accordingly.

● Significant hardware cost reduction of up to 30% with this newly developed solution.

● Leverage 8 channel DAQ card, enabling simultaneous sampling of up to 1.6M vibration signals per second.

● Synchronization of 32 channels, allowing for the collection of an impressive 6.4M sampling data per second.

Case 6: Fast Roaming Accelerating Solution of AGVs

For the seamless transmission of AGV control data, establishing a dependable dual-band Wi-Fi network with rapid roaming and signal switching capabilities is crucial. ProX PC's EKI-1361 Wi-Fi clients offer fast-roaming speeds of 100ms and can seamlessly switch between multiple access points (APs). This compatibility ensures a smooth and uninterrupted flow of real-time data communication for AGV operations

● Supports 802.11r Wi-Fi and enables fast roaming signal switching within 100ms, without any AP constraints.

● Facilitates seamless communication through serial, Ethernet, and Wi-Fi connectivity options.

● Wide power input range of 12 ~ 48 VDC with redundancy, ensures reliable operation even in challenging conditions.

Edge Computing Products

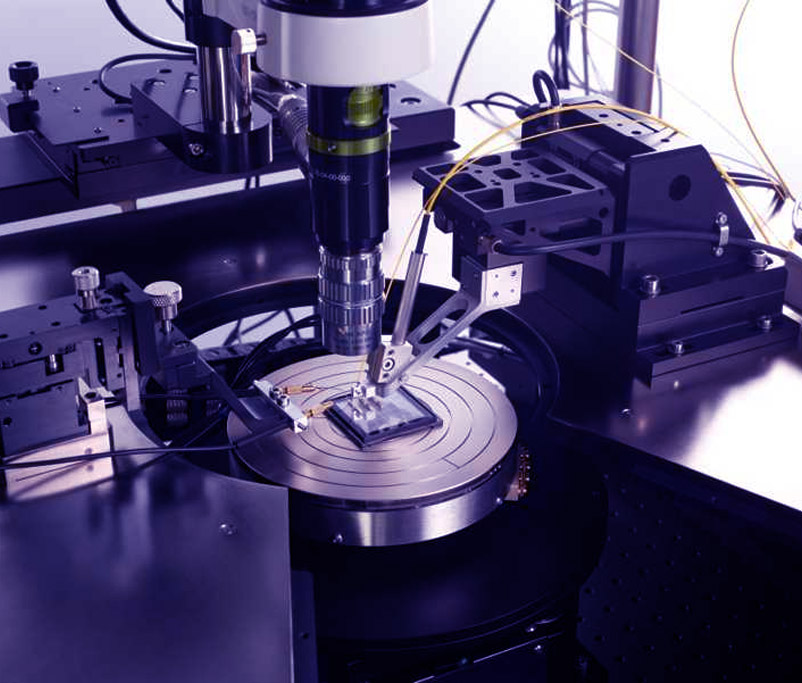

ProX Micro Edge Orin Developer Kit

Learn More

ProX Micro Edge Orin NX

Learn More

ProX Micro Edge Orin Nano

Learn More

ProX Micro Edge AGX Orin

Share this: