For Professionals, By Professionals

Discover ProX PC for best custom-built PCs, powerful workstations, and GPU servers in India. Perfect for creators, professionals, and businesses. Shop now!

SERVICES

WE ACCEPT

Outline

Case 1- AI Predict Maintenance for Energy

Case 2-Traffic Monitoring

Case 3-Improving Wait Time at Major Intersections

Case 4-Tracking Healthy Bee Hive Populations with the Latest in Machine Vision Technology

Case 5-AI Optical Sorting and Classification in Coffee Bean Processing

Case 6-A New Era in Shrimp Farming: AI-Powered Monitoring and Control

Case 7-AI-Based Detection System for Livestock Health Management

Case 8-Revolutionizing Egg Production: An AI-Based Optical Inspection System

Case 9-Maximizing the Efficiency of Agricultural Robots

Case 10-An AI Powered Fruit Prediction System for Optimal Harvest Management

Case 11-Quality Control in Cookies Factory

Case 12-AI Monitoring Safeguards Hygiene and Quality in Food Factory

Case 13-AI Defect Inspection for Textile

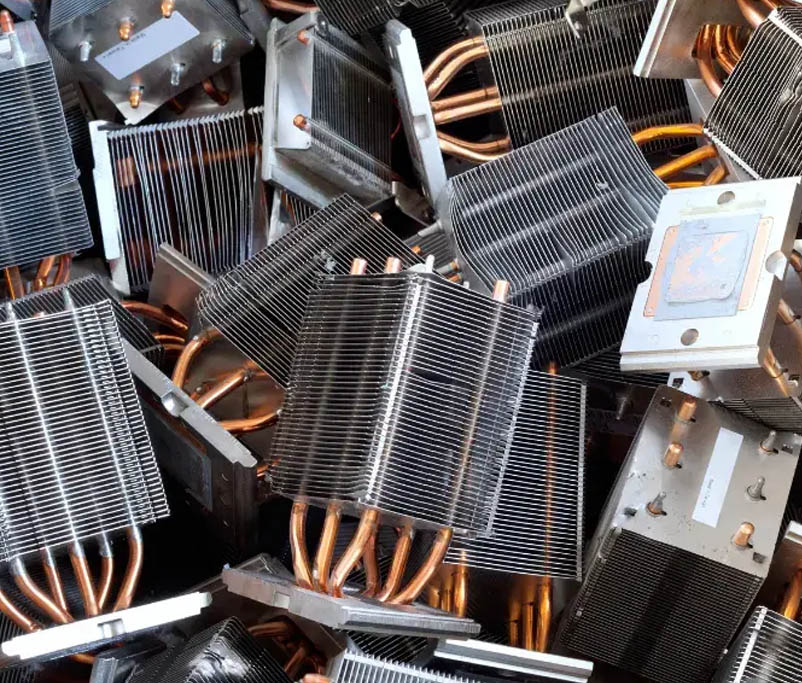

Case 14-Multiple-model AI Inspection for Heat Sink

Case 15-AI Analysis: Identifying Critical Production Bottlenecks

Case 16-Edge AI Secutiry System Based on Standard IP Video Cameras

Case 17-AI Empowered Indoor & Outdoor Facility Safety

Case 18-"Screen Data Extractor(SDE)" Aimed at AI Smart Factory Transformation

Case 19-Explore Potential Applications for Self-Driving Vehicles

Case 20-Comprehensive Sanitization with the UV Disinfection Robot

Case 21-AI-Enabled Safe Driving Environment for Logistics Fleets

Related Products

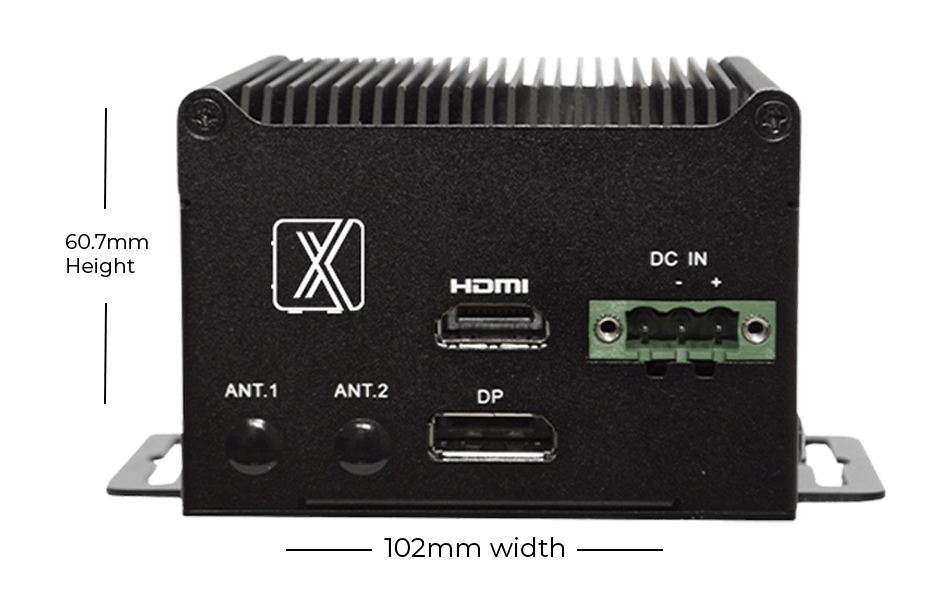

ProX PC AI Edge Solutions – Micro Edge Orin Jetson series, powered by full NVIDIA® Jetson™ platform, which gets all the performance of a GPU workstation in an embedded module.Featuring strict validation to ensure thermal, mechanical, and electrical compatibility, plus industrial-grade anti-vibration, high temperature operation capabilities, and modular, compact-sized design, ProX PC’s Micro Edge Orin Jetson series are perfect hardware platforms for the surveillance, transportation, and manufacturing sectors.

Case 1- AI Predict Maintenance for Energy

From 2016 to 2022, the wind power generation maintenance market in China has shown a year-on-year growth trend. As of the end of June 2023, China's wind power generation capacity is approximately 340 million kilowatts, showing a year-on-year growth of 17.2%.

Leveraging extensive real-case data, Chinese wind turbine equipment manufacturers have developed highly accurate AI models. The precision of ice accretion detection is over 95%, crack detection accuracy exceeds 95%, and lightning strike recognition accuracy surpasses 80%.

Case 2-Traffic Monitoring

ProX PC Micro Edge Orin leverages AI inference technology to perform traffic monitoring on massive amounts of collected data; surpassing traditional vehicle recognition methods used for object tracking.

Micro Edge Orin fulfills deep learning computing requirements at the roadside, where metadata is packaged and transmitted to the central control room. It also provides multiple interfaces to integrate with other traffic equipment.

Case 3-Improving Wait Time at Major Intersections

Taipei’s traffic lights’ lengthy countdowns exist to provide fixed and enough time for pedestrians to safely cross wide roads. Such arrangements burdensome around midnight when fewer pedestrians and vehicles traverse Taipei’s streets.

After deploying this AI system, night wait times at red lights on arterial roads decreased by 35% and arterial roads green light periods increased by 7 ~ 79%. Also, it reduces carbon dioxide emissions by around 23 tons every year and results in an annual economic benefits of around TWD 1.83 million for each intersection.

Case 4-Tracking Healthy Bee Hive Populations with the Latest in Machine Vision Technology

In recent years, beekeepers have been reporting they are losing, on average, 30 percent of all honeybee colonies each winter. This is twice the loss considered economically tolerable. Similarly, wild bee populations are also in decline.

So, we must learn more about bee hive health, bee behavior, and queen failure in an effort to limit future bee hive loss. Now, to get a complete picture of the health of the bee hive, SAS had to be able to collect, visualize a variety of IoT data and use AI analyze from video and audio data.

Case 5-AI Optical Sorting and Classification in Coffee Bean Processing

To ensure the quality of coffee beans for international trade, they must undergo a screening process to detect issues such as discoloration, fermentation, mold, insect damage, and broken or chipped shells before roasting.

However, manual sorting is laborious and prone to errors caused by fatigue, resulting in inconsistent quality. ProX PC offers AI-powered solutions for coffee producers to analyze and sort beans based on various characteristics throughout the entire supply and value chains.

Case 6-A New Era in Shrimp Farming: AI-Powered Monitoring and Control

Shrimp farming has long been a lucrative industry, but it faces challenges related to inefficiencies and waste. However, artificial intelligence (AI) is emerging as a crucial driver of efficiency and sustainability in this industry.

By utilizing AI for monitoring and management purposes, farmers can optimize feeding protocols and maintain the health of shrimp, thereby reducing waste, improving feed conversion ratios, and increasing shrimp production.

Case 7-AI-Based Detection System for Livestock Health Management

Farmers have struggled to identify and take timely action against animal diseases that threaten the lives of their livestock and significantly impact dairy production and food security.

However, with AI-based early detection systems for livestock health management, farmers can easily identify sick cows and take prompt action to prevent further spread of disease. The ProX PC system is designed to check the body temperature of each cow using AI and infrared vision.

Case 8-Revolutionizing Egg Production: An AI-Based Optical Inspection System

AI-based optical inspection systems are being used by egg producers to improve the quality of their eggs that get delivered to consumers. By detecting and rejecting low-quality eggs before they reach consumers, these systems help identify and remove eggs with cracks, discolorations, and other defects.

This technology reduces the risk of human error and labor costs, as it automates the inspection process, reducing the need for manual labor. The system is designed to provide high-speed and high-accuracy inspections, which saves time and resources.

Case 9-Maximizing the Efficiency of Agricultural Robots

The agriculture industry is facing a decline in fruit-picking capacity due to an aging rural population, but technology such as robotics and AI are offering a solution.Harvesting robots equipped with AI models and image processing can identify mature fruit and collect them using a robotic arm, resulting in efficient and accurate fruit picking.

The use of these robots addresses the declining capacity of the aging rural population while also increasing efficiency and reducing production costs. Advanced farms have already implemented robots to increase productivity.

Case 10-An AI Powered Fruit Prediction System for Optimal Harvest Management

As the demand for fresh produce continues to grow, methods for predicting fruit yields are becoming more efficient and reliable. In addition to increasing productivity and optimizing commercial and operational decisions, farmers are now able to accurately and quickly detect and count fruit using hyperspectral imaging and deep learning algorithms.

Using AI to forecast fruit yields can result in increased profitability and more efficient supply chain management for farmers.

Case 11-Quality Control in Cookies Factory

To maintain consistent quality for bakeries, Micro Edge Orin deploys various AI models to ensure that all cookies are well baked in the production line.

Compared to traditional quality control procedures performed through visual inspection, AI inference detects subtle levels of difference in how individual cookies are baked, adjusts the oven to meet quality standards, and avoids under-baked or overbaked products.

Case 12-AI Monitoring Safeguards Hygiene and Quality in Food Factory

To prevent food contamination during processing, workers are required to scrub their hands for at least 20 seconds and comply with six-step process requirements. However, for managers of food processing plants, such strict regulations are cumbersome.

Food processing companies can greatly benefit from a system that can monitor handwashing and enforce strict handwashing requirements while ensuring that factories remain productive and efficient. An AI system can accomplish this and instantly send out notifications to managers when problems occur.

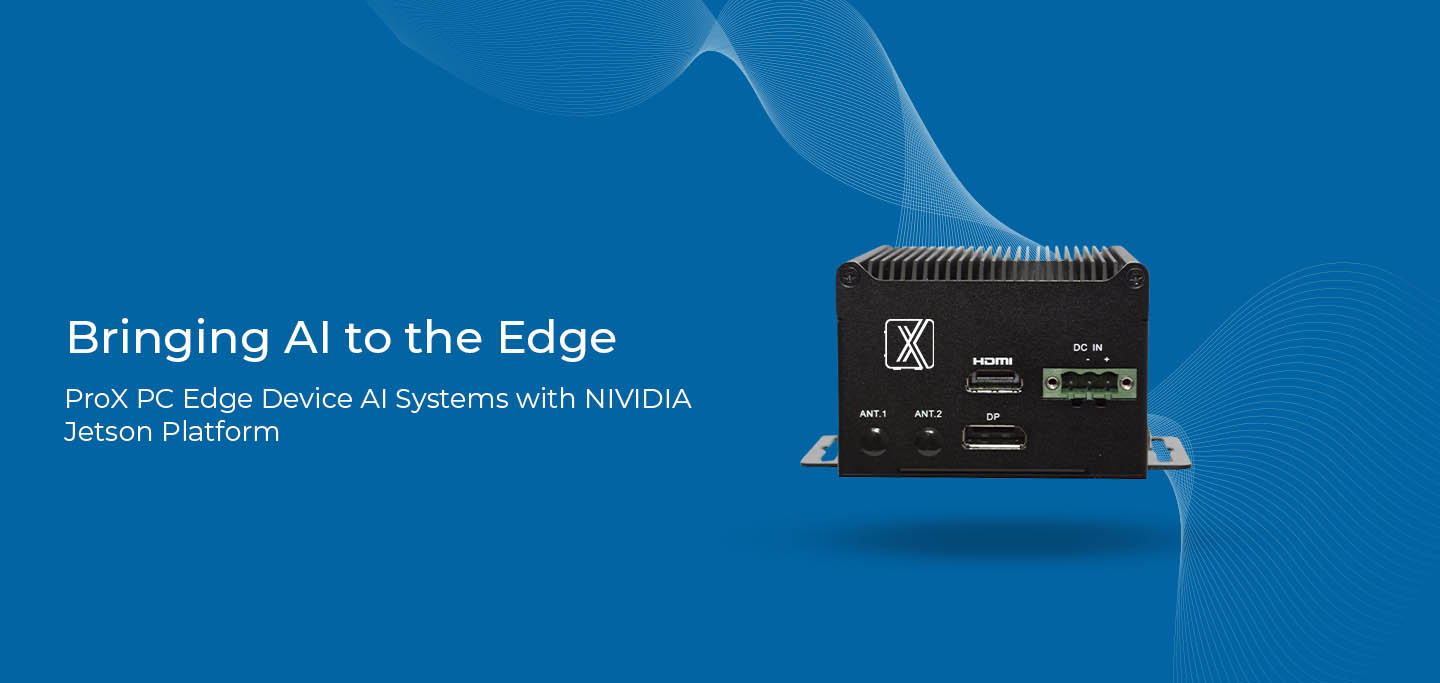

Case 13-AI Defect Inspection for Textile

AI inference requires high computation and needs a GPU-based solution to accelerate the computation. Micro Edge Orin is powered by an NVIDIA® Jetson AGX Xavier™ GPU and is employed as the edge AI system. Micro Edge Orin's great processing power makes it possible to automatically inspect high-precision textile goods with better speed and accuracy.

Textile defect inspections using AI inference technology can efficiently identify the most subtle defects and ensure high quality products.

Case 14-Multiple-model AI Inspection for Heat Sink

ProX PC Micro Edge Orin conducts AI image analysis to compare and identify heat sinks with appearance defects.This is made possible by feeding AI model training system with images of defective products that collected from clients, prior to the import of software and hardware. After AI model completes relevant training, the trained models are placed into the Micro Edge Orin.

AI visual inspection can then be conducted to evaluate the flatness and identify crushes, stains, scratches and other defects that are difficult to categorize through general physical rules.

Case 15-AI Analysis: Identifying Critical Production Bottlenecks

The Human Factor Information Datamation AI System uses cameras to record worker actions and then analyze images and video through AI inference. This system assists foundries in identifying bottlenecks and improving production efficiency.

Five major electronic manufacturing service foundries adopt this systems. With the aid of AI deep-learning software, factories increased their Unit Per Hour (UPH) by 5% within only two months.

Case 16-Edge AI Secutiry System Based on Standard IP Video Cameras

By using Edge AI, video streams from regular cameras can be analyzed in real time at the network edge and used to make critical security decisions. They can detect if triggered events are true intrusions or just false alarms, and they can instantly send notifications directly to your mobile phone with recorded video and pictures. Best of all, there is no additional cost on a security system, no expensive installation of sensors, and no high maintenance costs, this is the perfect solution for using your pre-installed security cameras to keep your family and assets safe.

Case 17-AI Empowered Indoor & Outdoor Facility Safety

Modern construction sites utilize real-time visual detection systems that analyze 20 to 30 live streams simultaneously. In these systems, visual AI increases the visibility of on-site workers and equipment to improve responsiveness to potentially dangerous situations — such as an employee carelessly approaching moving machinery. Real-time video feeds are available via the cloud to any device with a screen. To avoid tragedies or accidents, real-time alerts are sent to screens; and via methods including SMS and email.

Case 18-"Screen Data Extractor(SDE)" Aimed at AI Smart Factory Transformation

GoodLinker and ProX PC designed the Screen Data Extractor (SDE) to address data collection issues by integrating software and hardware. ProX PC’s Micro Edge Orin industrial-grade edge AI computer leverages the GoodLinker OCR recognition, yielding an excellent SDE solution. This system exploits VGA/HMI data output to ocular-recognize and record data presented on screen. SDE is an external device; as such, data collection can be completed with minimal impact on the production plan and production line.

Case 19-Explore Potential Applications for Self-Driving Vehicles

In recent years, autonomous driving technology has advanced rapidly. However, because Taiwan’s automobile industry is driven by market demand, the development of autonomous passenger vehicles is limited. Consequently, the Taiwanese government is emphasizing self-driving buses in its efforts to promote autonomous driving technology.

Case 20-Comprehensive Sanitization with the UV Disinfection Robot

Under the ravaging COVID-19 pandemic, periodic and frequent disinfection of the environment is also a necessity to eliminate the threat posed by the virus. Bysending manpower for disinfection operations is extremely dangerous, especially in high-risk fields, where the slightest human error may cause infection sources to leak out, even starting an outbreak. By replacing humans with robots, the risk of infection can be significantly lowered, while a safe environment can be effectively maintained.

Case 21-AI-Enabled Safe Driving Environment for Logistics Fleets

Many logistics fleets are installing AI surveillance systems in their trucks to ensure successful goods delivery and driver safety. As some vehicle surveillance systems lack continuous learning capabilities; they typically base their judgements on predetermined contingencies, resulting in misjudgments. ZH-AOI, an expert AI solution provider, built hundreds of sets of AI Fleet Management Systems for an e-commerce fleet last year.

Related Products

Share this: