For Professionals, By Professionals

Discover ProX PC for best custom-built PCs, powerful workstations, and GPU servers in India. Perfect for creators, professionals, and businesses. Shop now!

SERVICES

WE ACCEPT

Contents

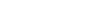

The use of computer vision in logistics is becoming more and more widespread. Hence, artificial intelligence (AI) vision is an emerging key technology in the field of logistics innovation and intelligent supply chains. Some innovations within categories such as AI visual inspection, analysis, and automated handling systems are leading the way within new technological trends in logistics.

In logistics and supply chain digitization with computer vision, image processing influences the handling and flow of goods, and the automation of logistical processes and supports human operators in logistics systems with cognitive, physical, and visual assistance purposes. In the following, we will outline the significant new trends in computer vision and image processing in logistics.

This article provides an overview of computer vision and visual AI applications in logistics:

About us: ProX PC powers the leading end-to-end computer vision platform. Leading logistics companies use our AI infrastructure to build, deploy, scale, and secure their computer vision applications. Get a demo for your company.

Computer Vision in Logistics

Due to the increasing global diversity of goods and globalization of markets, supply chains, and logistics systems are becoming more complex and challenging. This results in an increasing need for automation and digitalization of existing processes and the related flow of information for logistics solutions.

Technology Trends of AI Vision

The implementation of smart logistics objects and smart logistics infrastructure aims to run processes as efficiently as possible. Therefore, sensor modules are used to gather information about logistics objects or infrastructure components. Computer vision allows efficient digitization of objects, environments, and humans with visual sensors.

In recent years, machine learning and deep learning methods have brought great breakthroughs in computer vision. Machine learning allows highly robust and accurate real-time image recognition and object detection. Compared to traditional machine vision, deep learning allows one to perform video analysis using the video of common, inexpensive surveillance cameras and is highly scalable. If you are looking to build and operate your AI vision systems, check out the end-to-end computer vision platform.

How computer vision systems with deep learning work in a nutshell:

(1) Cameras provide the image or video

(2) Image processing algorithms analyze the visuals (Al model)

(3) Al model outputs are used to automate specific tasks

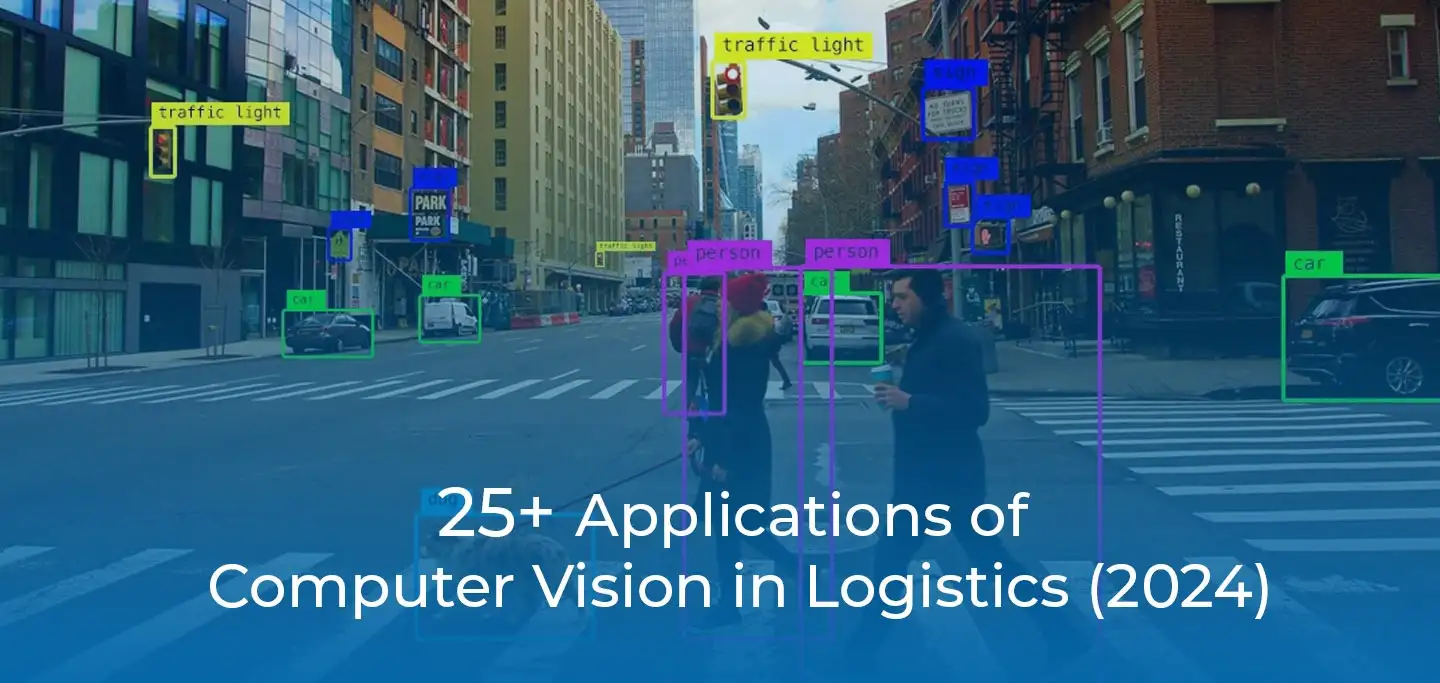

Scaling AI Vision with IoT (Edge AI)

New trends move machine learning tasks from the cloud to the edge, closer to the sensor. Hence, AI vision is increasingly designed as Internet of Things (IoT) nodes. Such nodes are connected edge computing devices that perform image processing but do not deliver pictures but state data of processes.

Moving machine learning from the cloud to edge devices makes it possible to run deep learning everywhere and create scalable computer vision applications. Also, edge computer vision systems have the advantage of being robust, private, decentral, cost-effective, and scalable. The ability to implement large-scale AI vision solutions enables a wide range of applications in logistics and distributed global supply chains.

General overview of edge computing with nodes (edge computers) connected to cameras

Best Applications of Computer Vision in Logistics AI

In the following, I will provide a list of the most important computer vision applications in Logistics. With the recent technological advances, we expect to see many more large-scale AI vision applications in logistics.

The following chapters provide over 20 detailed use cases and examples of the most innovative applications of visual AI in logistics.

Traceability and Tracking of Objects

Smart tracing applications aim to identify and localize logistics objects such as goods, containers, vehicles, or persons within logistics systems. It can be achieved by attaching optical codes to objects such s barcodes or QR-codes and using image processing algorithms to capture and read the optical codes.

Vision-based Good Identification

Such identification systems are widely popular for identifying incoming and outgoing goods in warehouses and distribution centers. Camera-based systems are used to read 1D barcodes (barcode scanning), 2D codes, or attached labels using optical character recognition (OCR). In port logistics applications, OCR systems are used to read container codes and license plates (ANPR) of trucks and delivery vans in real time.

Container Number Recognition System

Computer vision has been used to recognize container numbers automatically. Number recognition is used to detect and locate containers in large-scale areas automatically. Regular security cameras provide a pre-processed visual image and feed it into an ML model. Visual container recognition is highly scalable and contactless, hence providing a method to track containers of different parties efficiently.

Good Localization Systems

In addition to identifying goods, AI camera systems can accurately localize codes for warehouse management. For example, the video stream of cameras installed on forklifts is used to localize packages or pallets equipped with optical codes.

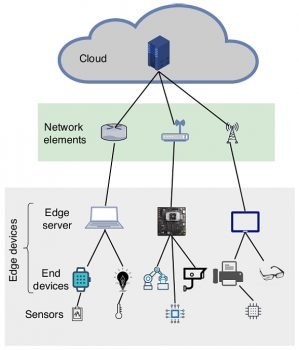

With modern convolutional neural networks (CNN), logistics objects can be identified and localized even without optical codes. Given the objects are optically distinguishable, machine learning algorithms identify and localize objects such as individual pallets.

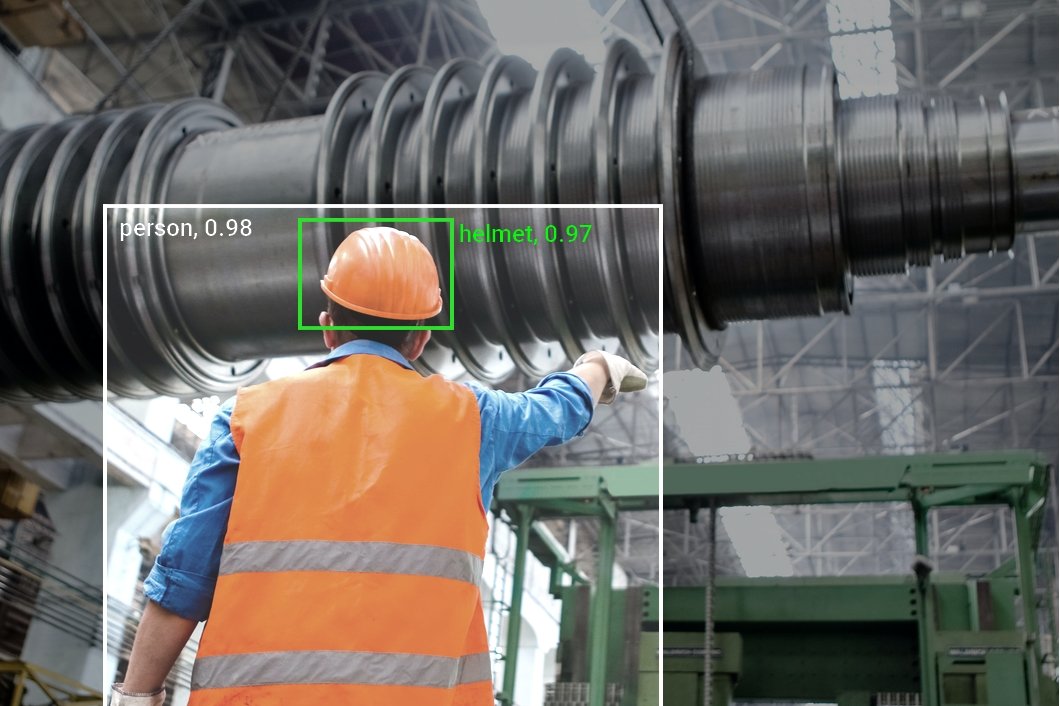

Example of object detection with deep neural networks (deep learning)

Volumetric Properties of Goods

In logistics processes, inventory management is critical for planning and billing quantities. Its automation enables significant time savings and optimization of operational efficiency. Hence, vision-based systems to detect the dimensions of goods are widely popular in detecting parcel dimensions on conveyor systems.

Goods and Pallet Dimensioning

The degree of automation in dimensioning is comparably low for goods usually handled manually, such as palletized goods. Hence, depth cameras based on time-of-flight (TOF cameras) or 3D stereo cameras are well suited to automate the measurement of dimensioning palletized goods with one single image frame. However, these approaches are still limited to applications that are outside the scope of legal metrology.

However, the cost advantages of camera-based AI systems over scanner-based systems enable use cases in mobile parcel dimensioning or product data acquisition. Standard surveillance cameras are also suitable for dimensioning palletized goods and packages, provided the systems and cameras are calibrated using specific reference points.

Inspection and Quality Control of Goods

Cameras for vision inspection tasks are integrated into the manufacturing and packaging processes of goods. An important use case is visual documentation and monitoring to prove the integrity of goods.

Visual Documentation and Monitoring

Cameras for vision inspection tasks are integrated into the manufacturing and packaging processes of goods. An important use case is visual documentation and monitoring to prove the integrity of goods.

Visual Anomaly and Defect Detection

Optical systems are further used in the logistics part of the supply chain to ensure the quality of goods by automated defect detection on incoming parcels or containers. AI camera systems are also suitable to detect anomalies in packages automatically.

Equipment Condition Monitoring

Equipment Condition Inspection and Monitoring

AI vision systems are widely used for conditions monitoring of logistics equipment. Practical examples include image processing technologies used for condition monitoring and predictive maintenance of long belt conveyors, which otherwise would need to be inspected manually.

Example of Equipment Detection with Computer Vision in Manufacturing

Early Defect Detection

In another application, thermal cameras provide images to detect defects in conveyor systems resulting from high friction. Moreover, depth cameras are used for condition inspection on belt conveyors to early detect belt displacements.

Occupancy of Storage and Traffic Areas

Since the availability of logistics areas is critical for efficient storage and transportation processes, several use cases provide ways to monitor space occupancy. Relevant objects include pallets stored in warehouses, vehicles parked in parking lots, and packages that are loaded onto delivery trucks.

Determine the Free Capacity of Transport Vehicles

Camera-based approaches have been implemented to determine the free capacity of transport vehicles, for example, with cameras oriented toward trailer gates. With reference points in images, the vision system can determine free-loading meters.

A related approach uses depth/stereo cameras mounted in the vehicles or outside at the gates. The current loading conditions and space for reduced operational costs and efficiency.

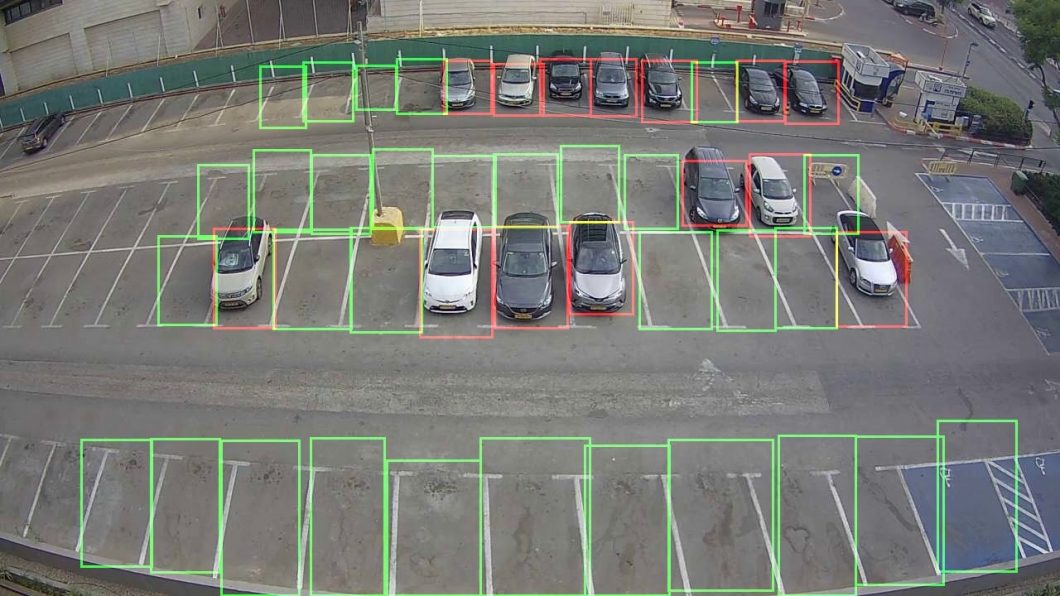

Docks and Parking Lot Occupancy Detection

The detection of available parking lots for vehicles with deep learning is a key solution in smart city applications of computer vision. In logistics, cameras and neural networks are used to detect if specific parking spaces are occupied by a car.

Computer vision technology can support yard and dock management by monitoring the occupancy of docks or parking lots. The loading states of forklifts are of interest to determine the coordinates of delivered goods in warehouses.

Parking lot occupancy detection for computer vision in logistics

Storage Bin Occupancy Analysis

This approach can be easily applied to other domains, for example, to detect free storage bins in warehouses. The occupancy of storage bins is used to detect critical process situations and to optimize transport routes.

Security and Protection of Infrastructure

Infrastructure and logistics facilities are the basis for logistics processes. Therefore, it is of great importance to protect them against internal or external hazards such as accidents, theft, terror attacks, and others.

Intrusion detection in logistics facilities

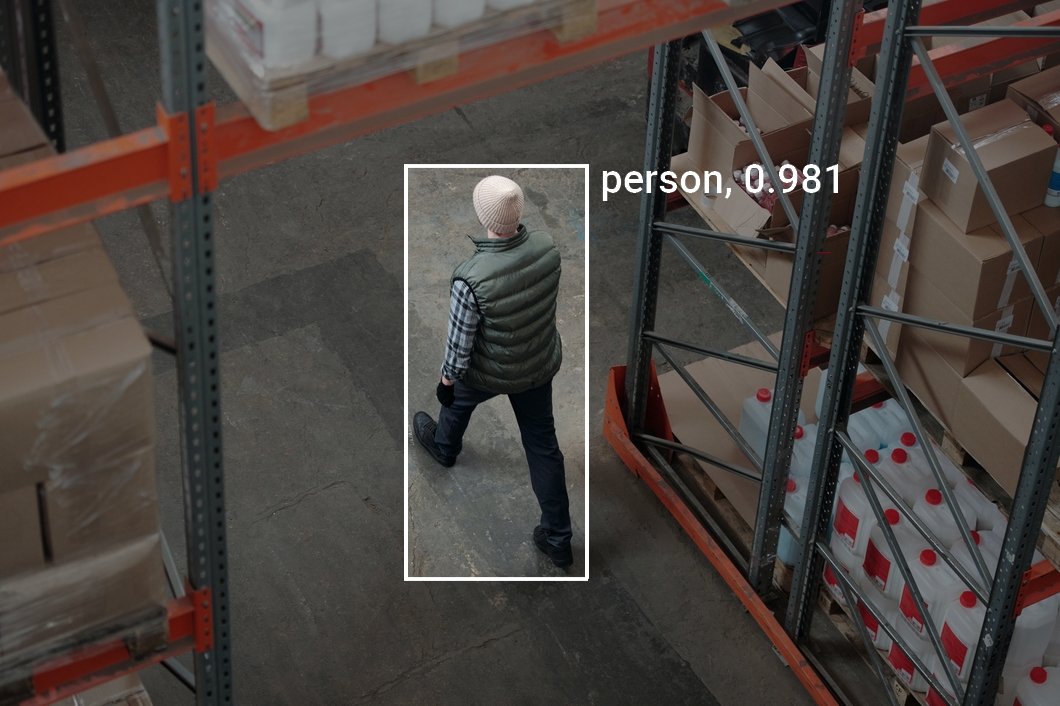

AI video surveillance is a widely popular, effective solution to increase security in logistics facilities such as warehouses. Modern deep learning methods allow intrusion detection with virtual fences to identify dangerous situations automatically. Related security applications include vehicle detection in restricted areas or large-scale face recognition.

Intrusion detection in logistics with deep learning

Crowd Detection and Behavior Analysis

Innovative systems include camera-based systems for people counting, crowd density estimation, and crowd behavior analysis to increase security at logistics facilities.

People counting application with deep learning

Due to legal requirements, privacy features are becoming increasingly important. Edge AI-based vision systems allow private on-device processing in real-time, without sending visual data to the cloud. This edge intelligence is also critical to ensure the continuous operation of vision systems despite connectivity timeout (offline).

Vision-based Anomaly Detection

With anomaly detection using machine learning, critical situations can be predicted to initiate preventive measures. For example, in freight transportation, camera-based systems can compute a freight fingerprint to detect potential security breaches along the transport chain.

Machine vision for defect detection

Process Modeling and Simulation

For planning and predicting the performance of logistics systems, simulation methods based on historical data are of great importance. Image recognition systems help collect and process real-time data for close-to-reality simulation.

Data Collection for Process Analysis and Optimization

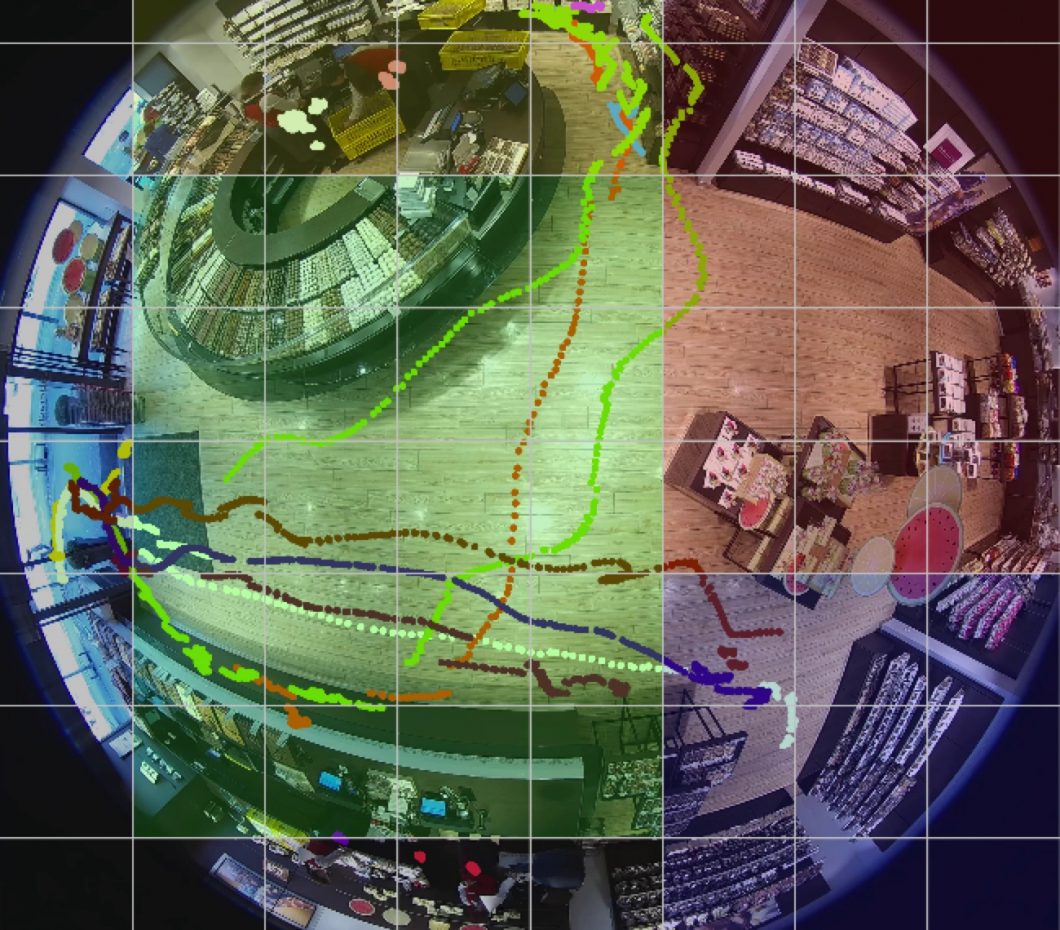

With object detection and object tracking, material flow parameters such as number, state, flow directions, throughput, and throughput time can be calculated. These parameters can be used for predictive analytics, simulation-based optimization, and evaluation of logistics processes.

Optimize Manual Picking and Packing

While there is a significant trend towards automation in logistics, the share of manual work in handling processes is still substantial. This is because of the diversity of goods which makes automation very challenging.

Wrong Placing Detection with Cameras

Since manual work is very error-prone, vision systems help to assist in picking and packing operations to reduce the error rates and save costs. For example, in picking assistance systems, cameras are used to detect the steps of moving the picking operations or detect the objects directly. Such vision systems help determine whether objects are placed correctly into a container and provide visual feedback about the handling process to indicate detected errors.

Human Error Detection with Deep Learning

Sophisticated vision systems use hand movement estimation with deep learning to detect whether the correct goods were packed. Other applications recognize objects inside a package and compare them to order lists. The use of deep learning allows new applications in logistics operations related to picking, packing, and placing, with many applications also being applied in retail.

Manually Operated Handling Systems or Vehicles

In logistics, goods are often moved with powered handling systems. In vehicles or systems where humans still perform navigation or maneuvering, vision systems assist and increase workforce safety.

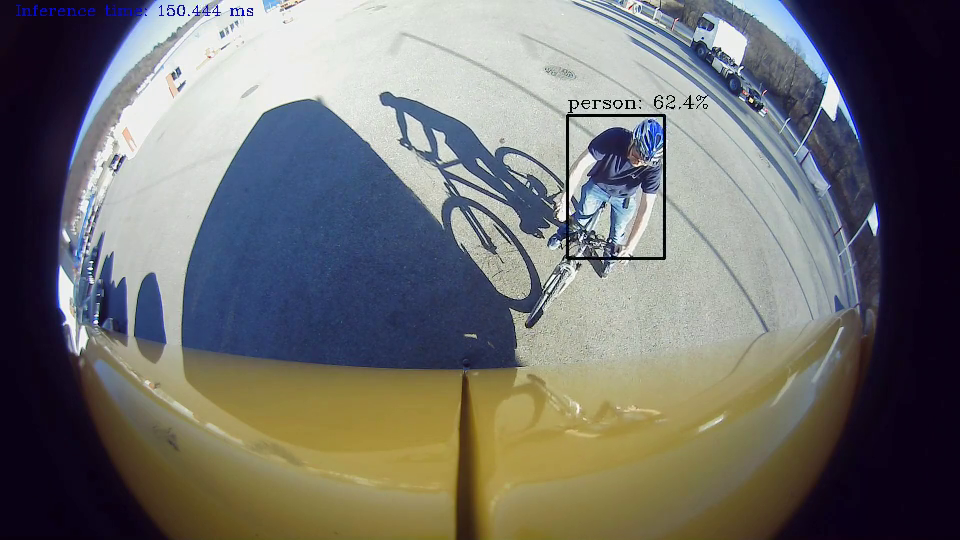

Vehicle Surround View and Deep Learning Assistance

Common vehicle assistance systems use cameras for transportation with forklifts, trucks, vans, or cranes by providing a rear or surround view. Thereby, cameras are mounted on vehicles with moving machine parts to assist operations and detect dangerous situations automatically. Deep learning vision systems detect obstacles and situations to generate warnings.

Person detection and vehicle surround view at a delivery truck

Automated Handling Systems

Automated material handling systems involve handling, loading, picking, and sorting operations along the supply chain. Here, modern image recognition supports this automation.

Loading and Unloading Robots

For example, robots that perform unloading operations use object recognition and pose estimation to detect individual goods (packages, sacks, etc.). Related applications involve de-palletizing of goods and robot-based order picking in distribution hubs and warehouses. Robots often use laser scanning systems for collision avoidance and camera-based systems for optical track guidance of automated vehicles.

Visual Documentation and Risk Management

Real-time Operations Monitoring

Since complex logistics operations involve a network of machine operations and human tasks, AI vision is used to analyze complex situations and provide critical information in real-time. In large logistics hubs with passenger terminals or event areas, visual monitoring systems help operators assess the situation at a glance.

Crowd behavior analysis application

AI Vision-based Risk Management Systems

Vision systems provide a way to reduce liability risks and improve risk management through visual documentation of liability transitions. There is a wide range of applications where cameras are used to assess risk scores of situations to reduce the risk of accidents or detect violations of guidelines and safety protocols.

Read More About the Latest Trends

Emerging technology and disruptive AI systems are expected to disrupt the logistics industry and improve general supply chain management. Ultimately, a fully optimized supply chain will result in improved customer satisfaction.

Related Products

Share this: